Blog-News

Achieving Homogeneous Mixtures from Extremely Different Materials in a Lancaster Mixer

The process of achieving homogeneous mixes from extremely different materials can pose a significant challenge in various industries. However, with advancements in mixing technologies, one notable solution is the counter-current mixing action of the Lancaster Mixer.

Understanding the Lancaster Mixer

The Lancaster K-Series Mixer is a high-intensity mixer known for its ability to produce uniformly mixed materials by subjecting them to intense mechanical agitation. This mixing technology utilizes a combination of a high-speed rotor, plow, and counter-rotating mixing pan creating gravity-driven flow patterns to ensure the thorough blending of materials, even when they possess diverse characteristics.

In-House Process Lab Renovations Augment Dedication to Mix Design Optimization

At Lancaster Products, we’ve been busy renovating our in-house materials processing laboratory, literally from floor to ceiling. Equipment upgrades and the addition of a production-sized mixer were implemented to provide customers with a more complete and accurate representation of their end product. The result has been a lab schedule that is busier than ever, and customers are excited with our ability to produce more variety and higher volumes of samples.

At Lancaster Products, we’ve been busy renovating our in-house materials processing laboratory, literally from floor to ceiling. Equipment upgrades and the addition of a production-sized mixer were implemented to provide customers with a more complete and accurate representation of their end product. The result has been a lab schedule that is busier than ever, and customers are excited with our ability to produce more variety and higher volumes of samples.

We always encourage customers to bring (or send) their materials to our lab in Lebanon, Pennsylvania for process testing because we feel the customer experience we deliver up-front is representative of the quality and support you can expect long-term. All customers work alongside our team of engineers and technical specialists with a total of more than 30+ years of experience in mix development and optimization, who will offer suggestions for real-time test adjustments, binder alternatives, scale-up options, and more. Ultimately, on-site testing offers the perfect opportunity to see and operate our equipment first-hand and experience just how easy it is to operate.

Save Time & Increase Yields by Mixing & Granulating in One Machine

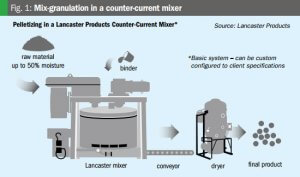

After more than 75 years in business and hundreds of installations worldwide, we still get excited when we demonstrate Lancaster Mixers ability for homogenous powder mixing and granulating in a single batch operation. With an average batch runtime under ten minutes for most applications, Lancaster Mixers ability to granulate produces high on size yields in a repeatable and predictable process. These “one-step mix-granulate” processes are utilized across a wide variety of applications including the production of fertilizer, technical ceramics, lightweight aggregates, beneficial re-use of waste, and more.

A typical Mix-Pelletizing Cycle looks like this:

A typical Mix-Pelletizing Cycle looks like this:

- Feed dry ingredients into mixer from weigh hopper(s)

- Dry mix and de-lump

- The de-lumping capability means the raw material does not have to be dry

- Add liquid or binder from separate weigh hopper(s)

- Wet mix and pellet formulation

- Dusting (optional – to stop pellet growth and clumping)

- Discharge

Effective Homogenization and Densification of Powders of Differing Densities

As published by Powder & Bulk Solids March 2023, pp. 13-14.

A common challenge faced by many customers is mixing two or more materials of differing densities into a uniform and homogenous mixture. Insufficient mixing can lead to particle segregation and de-mixing during transport or storage.

The Lancaster line of high-shear counter-current mixers excel at the rapid homogenization of bulk powders, including those of differing densities. For some applications, dry mixing operations can be as brief as 30 seconds or less.

This case study will demonstrate how Lancaster Products high-shear counter-current mixers can effectively homogenize these powders into a uniform mixture, while increasing the overall mixture density in the absence of added moisture. The counter-current mixing action is achieved by rotating the mixing rotor and mixing pan in opposite directions. Strategic manipulations of the speeds of the mixing tools can produce a uniformly homogenous mixture in a short period of time.

Increasing Throughput with Continuous Batch Processing

Part 4 of a 4-part blog series: “Enhanced Mix-Granulation in a Single Machine“

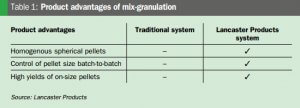

The precision mixing and granulation of mineral and organic fertilizer ingredients are essential to meet growing market demand for high-value, complex crop fertilizers. Furthermore, the ability to mix and granulate in a single machine offers fertilizer manufacturers both operational and product quality advantages over traditional granulation methods.. Click Here to download the complete article in pdf format as published by BCInsight Ltd in Fertilizer International May|June 2022, issue 508, pp. 34-37.

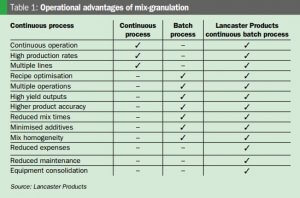

Batch processing of complex fertilizers offers both greater product accuracy and high yield outputs. The other key advantages of a batch process are recipe optimization and mix homogeneity. In fact, there are no real downsides because – with a continuous batch configuration – these important benefits can be realized simultaneously with the consistent throughput and high production rates of a continuous production line.

Batch processing of complex fertilizers offers both greater product accuracy and high yield outputs. The other key advantages of a batch process are recipe optimization and mix homogeneity. In fact, there are no real downsides because – with a continuous batch configuration – these important benefits can be realized simultaneously with the consistent throughput and high production rates of a continuous production line.

Enhanced Product Characteristics and Reproducibility

Part 3 of a 4-part blog series: “Enhanced Mix-Granulation in a Single Machine“

The precision mixing and granulation of mineral and organic fertilizer ingredients are essential to meet growing market demand for high-value, complex crop fertilizers. Furthermore, the ability to mix and granulate in a single machine offers fertilizer manufacturers both operational and product quality advantages over traditional granulation methods.. Click Here to download the complete article in pdf format as published by BCInsight Ltd in Fertilizer International May|June 2022, issue 508, pp. 34-37.

In complex fertilizers, thorough mixing of individual nutrients (e.g., N, P and K macro-nutrients plus secondary nutrients and micronutrients) is required to ensure maximum agronomic effectiveness without over/under application to the field. The multi-tool mixing action in counter-current technology delivers this, providing homogeneous mixing with rapid mix times.

In complex fertilizers, thorough mixing of individual nutrients (e.g., N, P and K macro-nutrients plus secondary nutrients and micronutrients) is required to ensure maximum agronomic effectiveness without over/under application to the field. The multi-tool mixing action in counter-current technology delivers this, providing homogeneous mixing with rapid mix times.

Because the pan, high speed rotor and plow are individually controlled, the mixer can create exact and repeatable conditions within the mixing cavity to produce specific products – e.g., granules of a specific size within a tight tolerance. Valuably, even slight adjustments to tooling speeds can produce different sized granules, shapes, densities, and yields.

Reduced System Complexity

Part 2 of a 4-part blog series: “Enhanced Mix-Granulation in a Single Machine“

The precision mixing and granulation of mineral and organic fertilizer ingredients are essential to meet growing market demand for high-value, complex crop fertilizers. Furthermore, the ability to mix and granulate in a single machine offers fertilizer manufacturers both operational and product quality advantages over traditional granulation methods.. Click Here to download the complete article in pdf format as published by BCInsight Ltd in Fertilizer International May|June 2022, issue 508, pp. 34-37.

Traditional fertilizer manufacturing typically requires multiple steps and many different pieces of machinery for drying, milling, mixing and agglomeration. Additionally, initial drying of high moisture raw materials is often required prior to processing – adding extra time and energy costs to the manufacturing process. Mixing and granulating in the same step in a high shear, counter-current mixer is advantageous as it reduces system complexity in several ways (Table 1):

Traditional fertilizer manufacturing typically requires multiple steps and many different pieces of machinery for drying, milling, mixing and agglomeration. Additionally, initial drying of high moisture raw materials is often required prior to processing – adding extra time and energy costs to the manufacturing process. Mixing and granulating in the same step in a high shear, counter-current mixer is advantageous as it reduces system complexity in several ways (Table 1):

Disc Granulation versus Mix-Granulation

Part 1 of a 4-part blog series: “Enhanced Mix-Granulation in a Single Machine“

The precision mixing and granulation of mineral and organic fertilizer ingredients are essential to meet growing market demand for high-value, complex crop fertilizers. Furthermore, the ability to mix and granulate in a single machine offers fertilizer manufacturers both operational and product quality advantages over traditional granulation methods.. Click Here to download the complete article in pdf format as published by BCInsight Ltd in Fertilizer International May|June 2022, issue 508, pp. 34-37.

Disc granulation is the method commonly used to produce fertilizer granules. This two-stage process typically employs a pin mixer (or similar mixer type) to pre-mix powdered materials to provide the feed for the disc pelletizer. The process generally requires the addition of large amounts of binder and water to create the finished product. This traditional type of granulation process is often not ideal as it generates lower yields of on-size pellets (1-3 mm) leading to high recycle loads.

Disc granulation is the method commonly used to produce fertilizer granules. This two-stage process typically employs a pin mixer (or similar mixer type) to pre-mix powdered materials to provide the feed for the disc pelletizer. The process generally requires the addition of large amounts of binder and water to create the finished product. This traditional type of granulation process is often not ideal as it generates lower yields of on-size pellets (1-3 mm) leading to high recycle loads.

NEW Heated Pan Option for K-1 Laboratory Mixers

The K-1 Laboratory mixer from Lancaster Products is now available with a heated pan option, and K-1 mixers currently in the field can be retrofitted with a heated pan as well. The heated pan provides consistent, controlled heat throughout the mixing chamber, and is ideal for recipes that require a very viscous binder such as molasses, wax, or tar. The addition of heat directly to the mix recipe increases the flow rates of viscous materials (particularly binders) which can prevent premature binding and incomplete mixing.

High Intensity Explosion Proof Mixers

Lancaster Products offers explosion proof mixers for high intensity mixing applications where the potential for explosions is present, such as mixing powders for 3D metal printing. Most of our Lancaster Mixers can be designed to meet explosion proof requirements such as:

- The ability to pump inert gas (such as Nitrogen or Argon) into the mix chamber to replace the Oxygen and eliminate the potential for spark caused by the presence of Oxygen.

- Instrumentation added to verify the removal of Oxygen in the mix chamber.