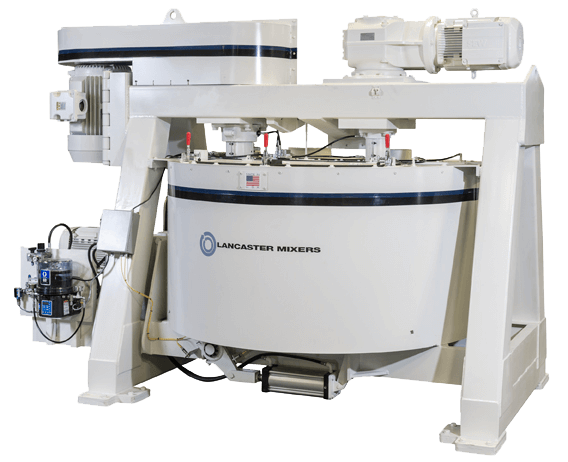

Using our proprietary mixing knowledge and technology, Lancaster Products high intensity K-series mixers use a counter current rotating pan and high energy rotor to mix and pelletize in a single machine.

The Lancaster Mixer produces high yield, high quality pellets from the most sensitive of materials with little binder. An extension of the granulation capabilities, our K Series mixers can grow granules and prills into larger sized pellets.

ONE MACHINE ONE PROCESS

Lancaster Products is at the forefront of providing high-value pelletizing solutions for our customers. Lancaster Products combines decades of mixing experience, working across multiple industries, with the finest granulating and pelletizing mixer technology.

Using our proprietary mixing knowledge and technology, Lancaster K-series Mixers use a counter-current rotating pan and high energy rotor to mix and pelletize in a single machine. The K-series mixers produce consistent and repeatable pellet sizes. Because Lancaster Products mixers can both mix and pelletize in the same operation it can supplant multiple pieces of mixing and pelletizing equipment in a process.

PELLETIZING APPLICATIONS

- Ceramics: Molding compounds, molecular strainers, proppants, dental compounds, cutting ceramics, grinding agents, oxide ceramics, grinding balls, ferrites

- Building materials: Porosity agents for bricks, expanded clay, pearlite

- Glass: Glass powder, carbon, lead glass mixtures

- Metallurgy: Zinc and lead ore, aluminum oxide, silicon carbide, iron ore

- Agricultural chemistry: Lime hydrate, dolomite, phosphate fertilizer, peat fertilizer, mineral compounds, sugar beet seeds

- Environmental protection

- Cement

- Filter dusts

- Fly ash

- Slurries

- Dusts

- Lead oxide

The Lancaster Difference: Counter-Current Mixing Technology

Our proprietary counter current mixing action allows the Lancaster Mixer to drastically reduce throughput times and increase pelletization yields when compared to traditional mixing and pelleting equipment. These improvements increase return on investment for our customers

ADVANTAGES OF PELLETIZED MATERIALS OVER LOOSE BULK MATERIAL

- Ease of transfer and shipping bulk materials handling specifically for superfine materials to prevent from going airborne for materials such as fertilizer, carbon black and fly ash

- Increases flowability of product for ease of feeding, pouring and processing

- Improves surface area of pellets for sintering, drying, melting, combustion

- Pelletized materials compact better than powders and allow for better handling and allow for recycling of waste materials

- Disposal of steel mill dust and particles, cement and lime kiln dust and friction material waste.

- Reclamation of waste from steel mill revert fines, coal and coke fines, copper precipitates, kiln dust and other materials collected during the process.

- Creation of Biomass pellets as a fuel source

Call 1-800-447-7351 or Contact Us to talk to a Lancaster Products Representative about your pelletizing needs.