Blog-News

New, Integrated Clean-in-Place Option for Lancaster Mixers

We are excited to announce the addition of integrated Clean-in-Place systems as an available option for all new Lancaster Mixers. Customer demand has been high for this feature as more materials processors are expanding their product offerings and running a greater diversity of recipes through our mixers, thus increasing the need for regular, complete cleaning between products. The ability to automate the cleaning process also helps to satisfy the need to improve efficiencies and counteract recent trends in labor shortages.

The Lancaster Mixer clean-in-place (CIP) system incorporates rotating nozzles permanently mounted in an optimal configuration that allows for 360-degree coverage of the mixing chamber without interfering with normal machine operation such as loading ingredients and discharging processed materials. High pressure pumps power the system to accomplish complete coverage with average cleaning cycles as short as 5-10 minutes. The ability to automate the process at pre-determined intervals ensures greater reliability and consistency of cleanliness and maintenance.

Owner Interview: How to Grow by Design with Curt Snyder

Re-published by permission from Value Prop and the Revenue Throughput Podcast.

Jose Palomino: Welcome again to the Revenue Throughput podcast. This is Jose Palomino, your host and our guest today is a CEO, owner, operator of a really fascinating company. He’s Curt Snyder, CEO of Lancaster Products based in Lebanon, PA, and they are a solutions company dedicated to improving material mixing and processing. They design and build complete mixing pelletizing and crushing systems for a wide range of industries and different materials and applications.

I’ve known Curt for years, and I’ve seen firsthand how he’s applied some best practices and principles to grow and thrive in a number of highly competitive markets. Well, let’s welcome Curt Snyder to the Revenue Throughput podcast. Hi Curt, glad to have you here.

Curt Snyder: Thanks for having me Jose, I appreciate it.

Jose Palomino: Yes, so Curt, in my introduction I mentioned how I just focused on one business right now. The Lancaster Products that I’ve certainly grew to know you best through initially, could you just provide a brief background how you came to to become the owner of Lancaster product?

What drew you into the world of heavy industrial manufacturing?

Curt Snyder: I had been working in mergers and acquisitions for probably close to 15 years prior, part of that was in aerospace, so it’s fairly complex, highly engineered heavy manufacturing type of product. I had been traveling the world, making acquisitions, and had a young family and quite frankly was tired of being away. So much so, when the opportunity presented itself, I was able to go out on my own and I found Lancaster Products, and Lancaster Products seem to be really interesting. A heavier manufacturing company with proprietary products with some really interesting technology. Also the owner was ready to retire. So, I was able to step in and and take it over about five years ago.

Visit Lancaster Products at Ceramics Expo 2021

Lancaster Products will be exhibiting at the Ceramics Expo Conference & Exhibition from August 30 – September 1, 2021 at the Huntington Convention Center, in Cleveland, Ohio and we’d love to see you there!

Join Lancaster Products at the International Powder & Bulk Solids Conference & Exhibition

Be our guest….Lancaster Products will be exhibiting at the Powder & Bulk Solids Conference & Exhibition, from August 24-26, 2021 at the Donald E. Stephens Convention Center in Chicago, IL and we’d love to meet you there!

Full Scale Mix Recipe Optimization in Lancaster K4 Mixers

This is the third video in our lab and testing series. The Lancaster Products Lab is equipped with a production-sized K4 mixer to test and optimize mix recipes at full scale. In this video, we are testing a clay type of material for pelletization.

The K4 mixer introduces a third tool, the low-speed plow, which, along with the rotating pan, transports material to the high-speed rotor. You can see how the high shear counter-current movement creates a rolling action which agglomerates the materials into pellets. The K4 mixer has a bottom discharge; the plow allows for the rapid and complete evacuation of the mixing cavity. After the mixer is fully evacuated, the bottom discharge closes, and reseals ready for the next batch.

Prototype Mix Recipe Optimization in Lancaster K3 Mixers

This is the second video in our lab and testing series. The Lancaster Products lab is equipped with a small production-sized K3 mixer to test and optimize mix recipes at a prototyping scale. In this video, we are testing a clay type of material for pelletization.

Looking inside of the mixing cavity, you see the counter-current mixing action. The pan rotates clockwise, and the high shear mixing tool spins counterclockwise. The mixing pan actively transports material to the primary mixing tool. Slowing the action down gives us a good view of how the Lancaster mixing action creates a tumbling that promotes agglomeration by rolling the particles much the same way as a snowball growing larger by rolling down a hill.

Proof of Concept Testing in Lancaster K1 Lab Mixers

Lancaster Products is dedicated to optimizing our customers’ mixing processes and recipes. This 3 part video series will focus on our on-site lab and testing capabilities. In this first video, we demonstrate proof of concept testing with a chicken litter material for a fertilizer product.

We use our K1 lab mixer during these initial tests. We load the K1 mixer with the test material and then program the steps and feeds. After the mixer begins, we add a liquid binder to it to allow the material to agglomerate into granules or larger pellets.

Rotary Table Feeders Turn Batch Processing to Continuous Batch Processing

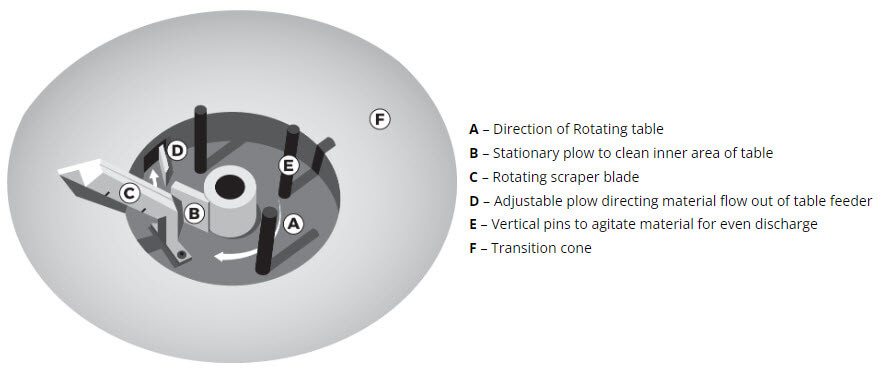

Rotary Table Feeder in Continuous Batch Process Line

Rotary table feeders act as a critical piece of equipment in Lancaster Mixers continuous batch processing lines. They provide a mechanical conduit to continuously meter and feed materials from each batch of material processed to the next process in line. The cone and cylinder over the table is used as a surge hopper to temporarily store the material batch while the table feeder continuously discharges the material. Their role may seem simple compared to the processing equipment they’re connected to, but is significant to maintaining continuous throughput and ensuring overall system performance.

Lancaster Products’ high shear mixers process materials in batches which allows for tight control over the physical properties of the end product and thus, higher on-size, homogeneous yields. Most batches are processed completely and ready for discharge in a matter of minutes. By positioning a Lancaster rotary table feeder under the mixer’s discharge chute and feeding product downstream to the next piece of equipment, the batch processing is converted to a continuous process.

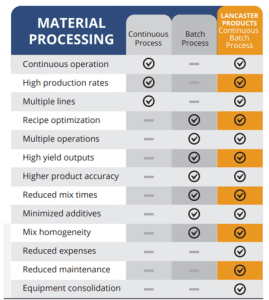

Improve Throughput Rates and Product Accuracy with Continuous Batch Processing

The Lancaster Products Continuous Batch Processing (system) design enjoys the benefits of both continuous and batch processing.

CONTINUOUS VS. BATCH PROCESSES

Continuous mixing processes are characterized by a consistent flow of material through the mixer where the discharge rate exactly matches the feed rate. The primary benefit of continuous mixing is steady state throughput to feed the next processing operation on the production line.

On the other hand, batch mixing processes typically are not in a steady state flow. Premeasured ingredients are added to the mixer, processed, and discharged in a single batch. The major benefit of batch mixing is the precise control of ingredient ratios, mix quality and product accuracy.

Controls Upgrades for Improved Industrial Mixer Performance

As part of Lancaster Products’ mission to deliver industry’s most effective and efficient materials processing equipment, we constantly evaluate for areas to improve our equipment design. While we often hear from machine operators how well our equipment holds up after decades of use in the most demanding environments, our equipment can benefit greatly from advances in software and technology. As we work to continually modernize our high shear mixers, the advances in controls technology can improve Lancaster Mixers performance and capabilities.

As part of Lancaster Products’ mission to deliver industry’s most effective and efficient materials processing equipment, we constantly evaluate for areas to improve our equipment design. While we often hear from machine operators how well our equipment holds up after decades of use in the most demanding environments, our equipment can benefit greatly from advances in software and technology. As we work to continually modernize our high shear mixers, the advances in controls technology can improve Lancaster Mixers performance and capabilities.

Lancaster Mixers counter current high shear mixing action provides for rapid homogenization along with the ability to granulate and pelletize within tight tolerances. Advanced controls design allows for a more accurate and customizable mixing process resulting in improved yields, rapid mix times and improved product reproducibility.