Part 2 of a 4-part blog series: “Enhanced Mix-Granulation in a Single Machine“

Download the Full ArticleThe precision mixing and granulation of mineral and organic fertilizer ingredients are essential to meet growing market demand for high-value, complex crop fertilizers. Furthermore, the ability to mix and granulate in a single machine offers fertilizer manufacturers both operational and product quality advantages over traditional granulation methods. Click Here to download the complete article in pdf format as published by BCInsight Ltd in Fertilizer International May|June 2022, issue 508, pp. 34-37.

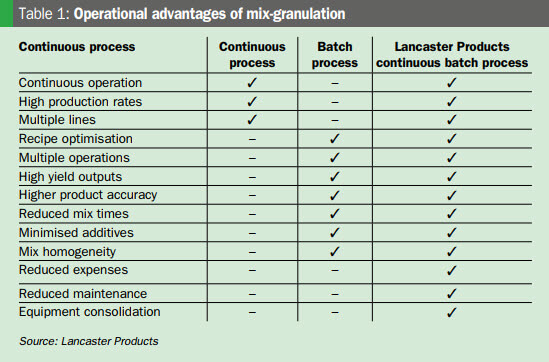

Traditional fertilizer manufacturing typically requires multiple steps and many different pieces of machinery for drying, milling, mixing and agglomeration. Additionally, initial drying of high moisture raw materials is often required prior to processing – adding extra time and energy costs to the manufacturing process. Mixing and granulating in the same step in a high shear, counter-current mixer is advantageous as it reduces system complexity in several ways (Table 1):

Traditional fertilizer manufacturing typically requires multiple steps and many different pieces of machinery for drying, milling, mixing and agglomeration. Additionally, initial drying of high moisture raw materials is often required prior to processing – adding extra time and energy costs to the manufacturing process. Mixing and granulating in the same step in a high shear, counter-current mixer is advantageous as it reduces system complexity in several ways (Table 1):

- Reduced physical footprint. The continuous batch process offered by Lancaster Products requires very little square footage due to its vertical design which employs gravity for material transport.

- Operates with high moisture materials. Initial drying and subsequent milling in the manufacturing process can also be eliminated or greatly reduced as the mix-granulation process handles raw materials with up to 50 percent moisture.

- Less maintenance and energy use. The replacement of multiple machines typically found in traditional pelletizing process lines with a single high shear, counter-current mixer translates into less maintenance, fewer points of failure and reduced energy usage.

- Optimized ingredients and lower operating costs. Precise batch recipes eliminate the ingredient waste that results from uneven mix distribution. Instead, much less binder and water is required because counter-current mixing technology is highly effective at thoroughly dispersing such additives throughout the main ingredients.

Contact us to learn more about how we can reduce the complexity of your mixing system.

717-273-2111