Part 3 of a 4-part blog series: “Enhanced Mix-Granulation in a Single Machine“

Download the Full Article The precision mixing and granulation of mineral and organic fertilizer ingredients are essential to meet growing market demand for high-value, complex crop fertilizers. Furthermore, the ability to mix and granulate in a single machine offers fertilizer manufacturers both operational and product quality advantages over traditional granulation methods. Click Here to download the complete article in pdf format as published by BCInsight Ltd in Fertilizer International May|June 2022, issue 508, pp. 34-37.

In complex fertilizers, thorough mixing of individual nutrients (e.g., N, P and K macro-nutrients plus secondary nutrients and micronutrients) is required to ensure maximum agronomic effectiveness without over/under application to the field. The multi-tool mixing action in counter-current technology delivers this, providing homogeneous mixing with rapid mix times.

In complex fertilizers, thorough mixing of individual nutrients (e.g., N, P and K macro-nutrients plus secondary nutrients and micronutrients) is required to ensure maximum agronomic effectiveness without over/under application to the field. The multi-tool mixing action in counter-current technology delivers this, providing homogeneous mixing with rapid mix times.

Because the pan, high speed rotor and plow are individually controlled, the mixer can create exact and repeatable conditions within the mixing cavity to produce specific products – e.g., granules of a specific size within a tight tolerance. Valuably, even slight adjustments to tooling speeds can produce different sized granules, shapes, densities, and yields.

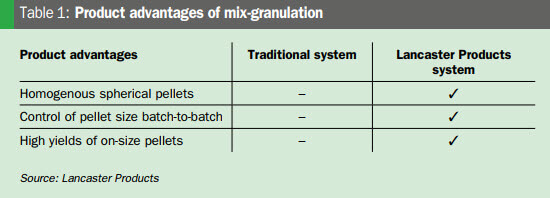

Mix-granulation also offers the following product quality advantages (Table 1):

- Homogeneous pellets with improved ingredient distributions

- High yields of on-size pellets with substantially less need to reprocess offsize product

- Versatility to control pellet size and characteristics on a batch-by-batch basis

Contact us to learn more about enhancing the characteristics of your product and reproducibility.

717-273-2111