Articles, Reports, and White Papers

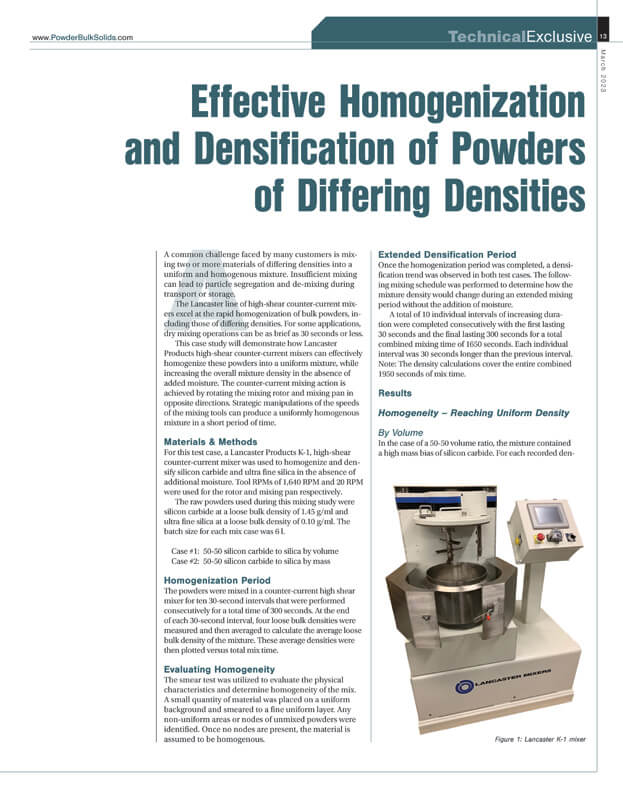

Effective Homogenization and Densification of Powders of Differing Densities

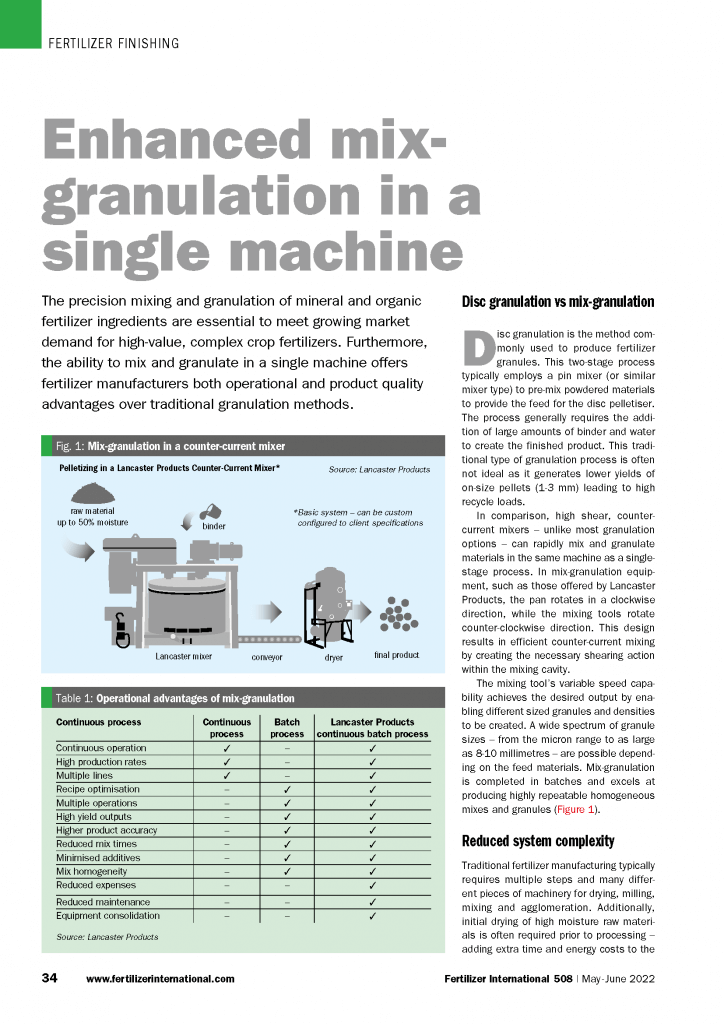

Enhanced Mix-Granulation in a Single Machine

A Simple Mixing Study for Perovskite Ceramics

Counter-Current Rotating Pan Mixers

Mix-granulating with K-series Mixer

Mixing Intensity versus Mixing Time

Refractory Applications

Variable Mixing Intensity with Lancaster K-Series Mixer can input custom-designed levels of mixing intensities, varying at will through the use of VFD control. The intensity range typically covers one order of magnitude, or roughly 1-10, to as much as 1-100. This wide range of intensity is more than adequate to handle any refractory applications for very short cycle times.

Ferrite Processing from A Mixing Perspective

With a Lancaster K-series high shear mixer, it is possible to adjust mixing tool speed, moisture level and time to control granule size, the degree of granule consolidation, producing optimum granule densities and hardness. Within limits, drier, smaller and less dense granules are preferred because they economize energy usage, and residence time in downstream processing.