Continuous Batch Processing

Is your material processed continuously or in batches? Different applications require different types of flows through the production line.

Continuous mixing processes are characterized by a consistent flow of material through the mixer where the discharge rate exactly matches the feed rate. The primary benefit of continuous mixing is steady state throughput to feed the next processing operation on the production line.

On the other hand, batch mixing processes typically are not in a steady state flow. Premeasured ingredients are added to the mixer, processed, and discharged in a single batch. The major benefit of batch mixing are the precise control of ingredient ratios and mix quality, as well as the ability to perform multiple operations (such as granulating) with the same machine.

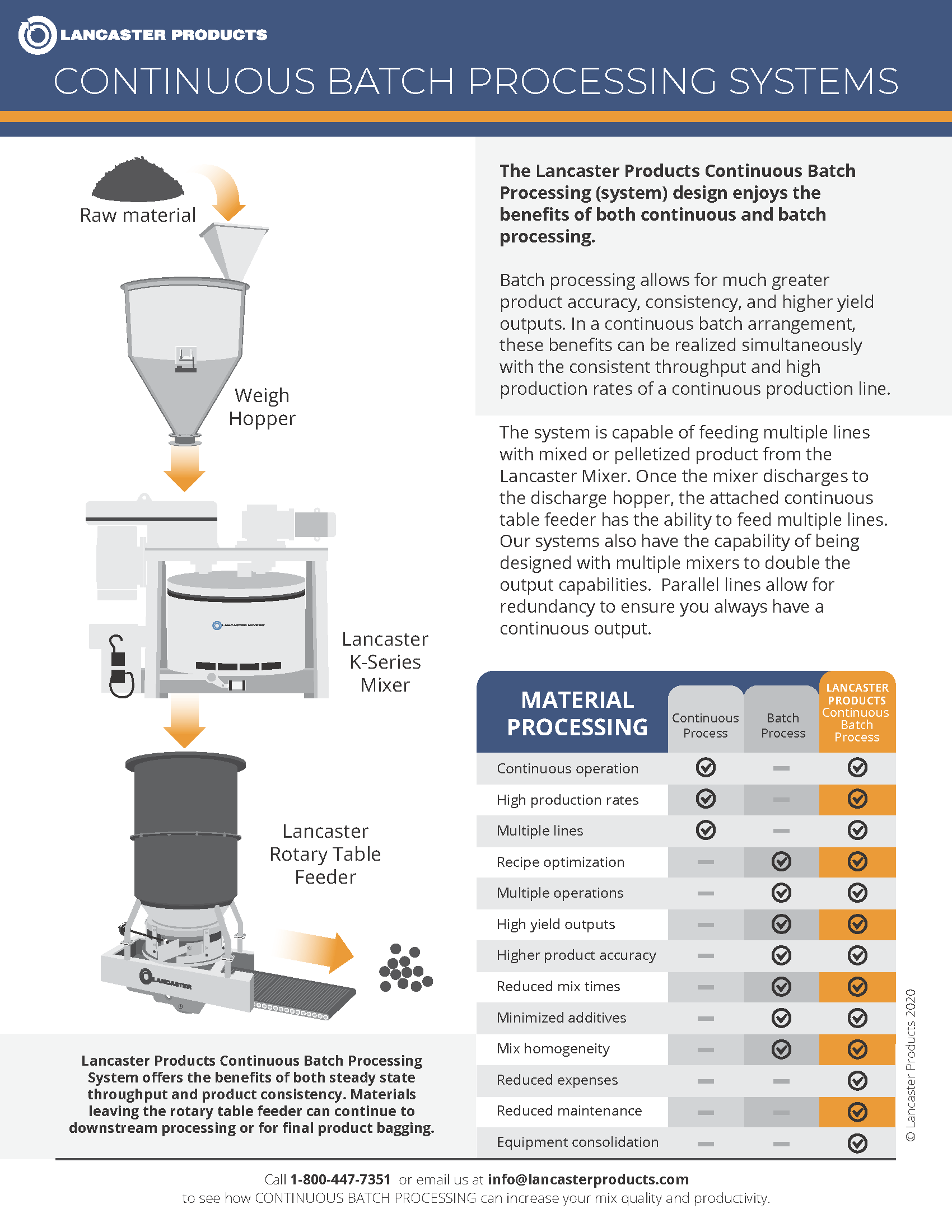

The Lancaster Products Continuous Batch Processing (system) design enjoys the benefits of both continuous and batch processing. Batch processing allows for much greater product accuracy, consistency, and higher yield outputs. In a continuous batch arrangement, these benefits can be realized simultaneously with the consistent throughput and high production rates of a continuous production line.

CONTINUOUS BATCH PROCESS: A HYBRID ALTERNATIVE

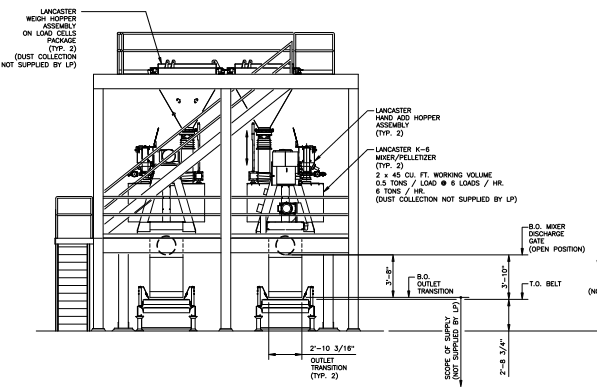

Lancaster Products utilizes hoppers above and below the high shear mixer to deliver a Continuous Batch Process. Weigh hopper(s) above the mixer utilize load cells to pre-weigh the ingredients. Once the mixer is ready for a new batch, a slide valve is opened, and gravity allows for a very quick fill of the mixer. When the hopper is empty, this slide valve will close to allow the weigh hoppers to prepare the next batch of ingredients to be mixed. The hopper directly below the mixer is called a discharge hopper. This hopper allows the mixer to discharge the entire batch, so that the mixer can be refilled. The discharge hopper then feeds material into a continuous table feeder or a conveyor. These hoppers below the mixer are typically sized at least 1.5 times the size of the mixer, ensuring a continuous material flow to the downstream processes.

LANCASTER PRODUCTS CONTINUOUS BATCH SYSTEM DESIGN

In a typical Lancaster Products High Shear Counter Current Mixer system, the pre-weighed dry materials are dry mixed. Then, if required, wet additives or binders are metered in, and a wet mix is completed. Finally, if the desired end product has a size requirement, the system moves to a granulating or pelletizing cycle before discharge. All of these steps are completed in a single machine, without intermediate material handling steps, complex process control of multiple machines or added inefficiency.

The Lancaster Products system is capable of feeding multiple lines with finished products. Once the mixer discharges to the discharge hopper, the attached continuous table feeder has the ability to feed multiple lines. Our systems also have the capability of being designed with multiple mixers to double the output capabilities. Parallel lines allow for redundancy to ensure you always have a continuous output.

The Lancaster Products System shown above is a Twin Mixer System with two continuous outputs. Each line has a weigh hopper on load cells above the mixer, and discharge/conveyance hoppers below each mixer.

Lancaster Products Continuous Batch Processing System offers the benefits of both steady state throughput and product consistency. Materials leaving the rotary table feeder can continue to downstream processing or for final product bagging.

MIX-GRANULATE or PELLETIZE IN A CONTINUOUS PROCESS

Granulating or pelletizing can easily be achieved within a continuous batch processing system by utilizing a Lancaster Mixer. Lancaster Mixers feature counter-current mixing technology which allows for reduced mix times, minimized additives, improved mix homogeneity as well as mixing and granulating/pelletizing in one-step. The counter-rotating pan and multi-tool configuration results in superior mixing and granulation in the same machine and process.

The capability to independently control the speed of the pan, high speed rotor and plow results in the most desirable final mixed/pelletized product. Altering individual tooling speed allows the mixer to create exact and repeatable conditions and shear within the mixing cavity that produce specific products – such as pellets of a specific size within a tight tolerance. Even slight adjustments to the tooling speeds combination can produce different sized granules, densities and yields. This gives the Lancaster Mixer the versatility to change the end product from batch to batch without altering the ingredients.

Traditional pelletizing processes require the raw material to be dried to less than 20%, then conveyed to a pulverizer/mill, onward to a pin mixer, and then to a disc pelletizer or pellet mill before being conveyed to dryer. The Lancaster Products High Shear Counter Current Mixer can mill, dry mix, wet mix, and pelletize in one machine, with higher moisture levels than traditional granulation equipment. This significantly reducing capital expenditure, maintenance costs and square footage required. Learn more about the benefits of pelletizing in a Lancaster Mixer.

The Lancaster Products Continuous Batch Processing system allows users the best of both worlds. For Continuous Processing applications, users now can take advantage of the precision of a Lancaster Mixer to improve product quality and precision, increase production line yields and throughputs while reducing additives to precise amounts. For Batch Processing application, users can now take advantage of a continuous production flow to improve output without losing any of the precision of the batch process. The Lancaster Products Continuous Batch Processing offering is a superior alternative to traditional production lines by offering the benefits of both types of processing with none of the drawbacks.

Call 1-800-447-7351 or Contact Us to see how CONTINUOUS BATCH PROCESSING can increase your mix quality and productivity.