How is your Lancaster mixer performing?

Are you noticing a drop in yields or inconsistencies in product quality?

This may be an indication that your high-speed rotor needs to be repaired or replaced.

The high-speed rotor is the primary mixing and pelletizing tool in industrial high shear mixers and in many ways, it is the most utilized part of the machine. But rotor wear is also a good leading indicator of your machine’s overall operating condition as it is a direct result of material processing. Chances are, if the rotor is worn, there is other preventative maintenance to be done.

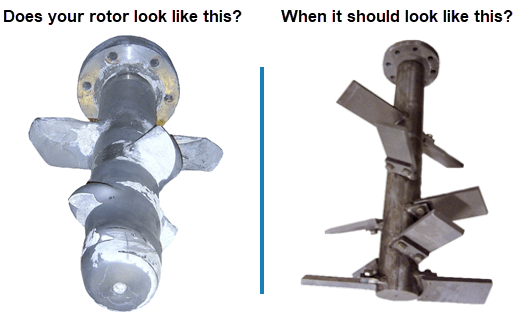

The images below show examples of rotor vane wear from an abrasive mix process over time. As you can see, it is fairly easy to identify the degree of wear by simple visual inspection in between batches. Rotor vanes exhibiting a loss in base metal should be replaced to maintain optimum batch yields and quality of end product.

Lancaster Products’ upgraded control systems can be programmed to alert the operator with a maintenance reminder when it’s time to inspect the rotor based on a predetermined interval of batch cycles to ensure that your Lancaster Mixer is performing at optimal levels.

NOTE: Because every material processed in our mixers is different, we encourage all machine operators to visually inspect the rotors with regularity, so the controls can be re-programed as needed to match the wear patterns in your process.

Not sure if your rotors need replacement? Contact us today because the Service Technicians at Lancaster Products are always available to assist with any on-site or remote diagnostics, repairs, and replacements of rotors or rotor vanes.

717-273-2111