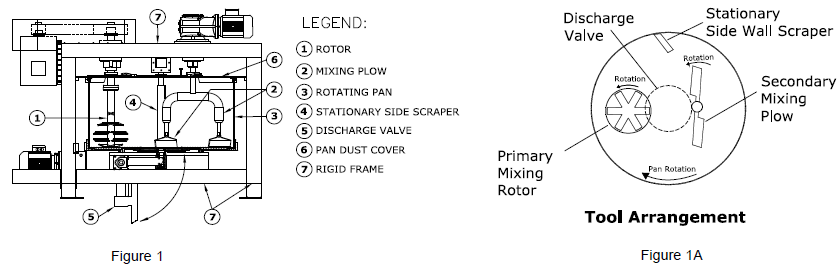

Counter-current rotating pan mixers incorporate a Rotor as the primary agitator in the mixing process (shown in the figure below). As discussed in a previous blog post (What is a Counter-Current High Shear Mixer?), global material transport within the pan (mixing vessel) is facilitated through the rotation of the pan itself, which also has the added benefit of producing more homogenous mixes with higher yields. Because the rotor is not needed for global material transport, it can be custom-configured in shape and speed as well as rotational direction to suit a variety of applications. It can change speed and direction at will if so needed. It also allows for fast liquid distribution without the use of atomizing nozzles.

An interesting and often useful design option is creating preferential material flow directions using various rotor shapes. A rotor can induce preferred directional material flows, increasing or decreasing frictional interaction among mix particles. It can create vortex-like downdraft or updraft material motions. It can also enhance spinning or shearing effects depending on design.

The capacity to custom-configure rotor speed enables the processing of a wide variety of materials, from free flowing powders, through plastic to slurries and liquids. This flexibility allows the mixer to input mixing intensity over a wide range, hence the ability to homogenize a batch in fractions of the time required by other mixer types. A counter-current rotating pan mixer can be configured to input as little as 5 HP per 1,000 pounds of mix at the low end, and as much as over 200 HP per 1,000 pounds at the higher end depending on process requirements.

Because the rotor and rotating pan work in concert, the mixer is able to perform a number of different actions in one machine and in a single batch. Counter-current rotating pan mixers are the equipment of choice for mixing, mix-pelletizing, reacting, de-dusting, slurrying, scrubbing, plasticizing as well as numerous other applications. There are several examples of customers using a Lancaster Mixer to perform multiple processing steps in a single batch.

One customer in the packaging industry used a Lancaster Mixer to break up cellulose fiber, mix in powders, and add in and distribute water to form a slurry in a single batch process.

Another manufacturer of beneficial absorbent products used the mixer to break up fibers, add in powders and pelletize in one batch.

A final example is a fertilizer manufacturer who used the Lancaster Mixer to mill oversized particles in a mix to a powder consistency, homogenize the powdered mix, distribute water and binder throughout the mix and then pelletize into a final product.

The Lancaster Mixer’s multifaceted capabilities can handle a diverse set of processes across a variety of industries.

The Lancaster Products counter current high shear mixer is an extremely versatile piece of equipment. It is capable of multiple processes in a single machine in a single batch simply by controlling the speeds and times of both the rotating mixing pan and rotor. For many of our customers the Lancaster Mixer is the heart and soul of their process. It provides a simplified process, reducing the number of steps and pieces of equipment when compared to traditional process designs. This simplified design has multiple benefits including; reduced maintenance costs, ease of operation and cleaning, higher output in a smaller footprint, increased capacity, and higher yields with tighter size distributions. The Lancaster Mixer is the ideal machine for customers looking to improve their process and reduce complexity.

Call 1-800-447-7351 or email us to talk to a Lancaster Products Representative to find out more about the advantages of a counter current high shear mixer