Lancaster Products has newly engineered their popular K-Lab Mixer. The K-Lab has been one of their fastest selling machines for testing, experimentation and development of new processes. It can beneficially add a new dimension to a mixing / pelletizing process that companies may not even know exist. The K-Lab mixers have proven for many companies to be a minimal investment with maximum dividends in product development.

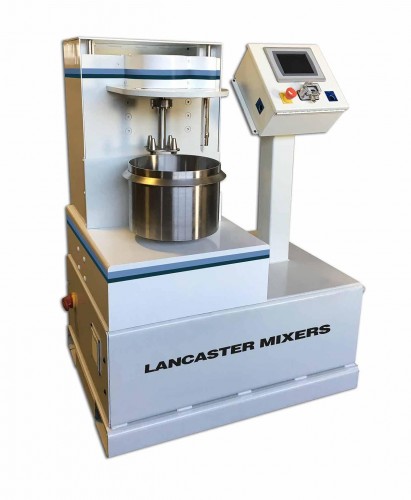

The New K-1 Lab Mixer

The New K-1 Lab Mixer

The K1-Lab’s enhanced mechanical design features a shorter, lighter, easier to handle and clean pan. The view port is larger than its predecessor and has a provision for sampling the material. This enables real-time adjustments to the mix. The K1-Lab also has a vastly improved, touch screen control allowing very specific electronically controlled speeds. A thermal probe gives a numerical report of temperature, again in real-time, permitting a better means of assessing whether temperature increase is due to friction or chemistry. There is a re-settable mix phase time that reads out in seconds. Total mix cycle times and a pre-programmable mix design are also provided. Motor speeds and power are recorded as well. The new control can also store and repeat mix cycles, as well as communicates with other devices.

Many companies have successfully used the Lancaster Products K-Lab mixers as “proof of concept” in product development, opening up new processes and markets for them. Once a mix is perfected in the K1-Lab mixers, we invite customers to come to our testing lab and replicate the results achieved in the K1-Lab using the K-4 production mixer.

The new K1-Lab mixer has now streamlined the mixing process of blending, pelletizing or granulating with much quicker times. Whether it is a ½ cu. Ft. capacity K1-Lab or a 210 cu. Ft. K-10, Lancaster Products is proud to be able to “take a tiny amount of this . . . add it to a lot of that . . . and have it result into something great!”

Come see us and the New K1-LAB at the Ceramics Expo in Cleveland, Ohio — April 26-28 —Booth #615