White Paper:

Evaluating the Effectiveness of Lancaster Products K-Series High Shear Counter-Current Mixers in Ceramic Processing

In typical ceramic processing applications, mixing / milling is performed using processes such as ball milling, which is a lengthy and energy-intensive process, often requiring processing times as long as 12 – 24 hours.

Could you achieve similar mixing in far less time?

A Simple Study

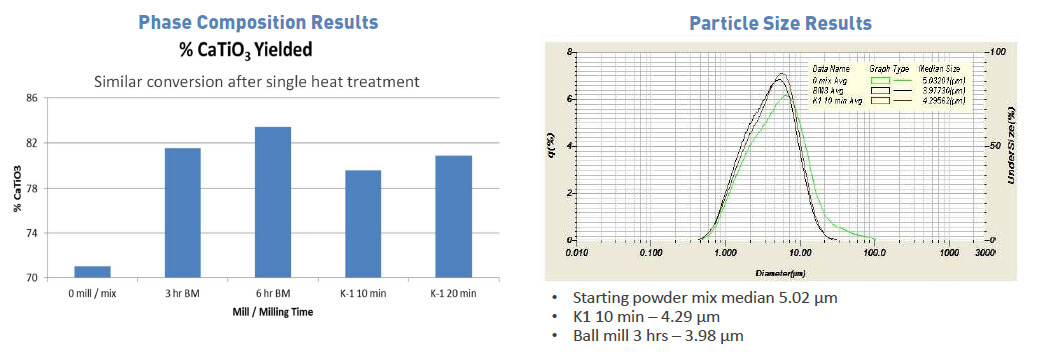

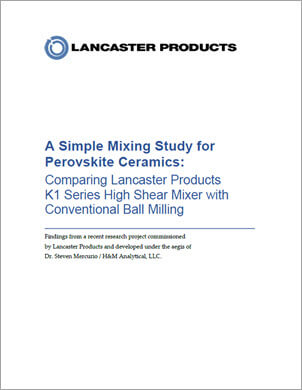

- Mix the components of a solid state reaction system and evaluate phase composition, particle size, and homogeneity (not shown here) of the heat treated powders (calcium carbonate and titanium dioxide.)

- Compare ball milling at set increments (3,6,12, and 24 hours) with powder sampled from the K-series mixer at shorter times (30 min. or less.)

Conclusions

Comparable mix quality and reduction in particle size in 10 to 20 minutes of mixing in a high shear, counter-current mixer yielded similar results as 3 to 6 hours of ball milling time.

Fill out the form below to download the White Paper today