Rotary Table Feeder in Continuous Batch Process Line

Rotary table feeders act as a critical piece of equipment in Lancaster Mixers continuous batch processing lines. They provide a mechanical conduit to continuously meter and feed materials from each batch of material processed to the next process in line. The cone and cylinder over the table is used as a surge hopper to temporarily store the material batch while the table feeder continuously discharges the material. Their role may seem simple compared to the processing equipment they’re connected to, but is significant to maintaining continuous throughput and ensuring overall system performance.

Lancaster Products’ high shear mixers process materials in batches which allows for tight control over the physical properties of the end product and thus, higher on-size, homogeneous yields. Most batches are processed completely and ready for discharge in a matter of minutes. By positioning a Lancaster rotary table feeder under the mixer’s discharge chute and feeding product downstream to the next piece of equipment, the batch processing is converted to a continuous process.

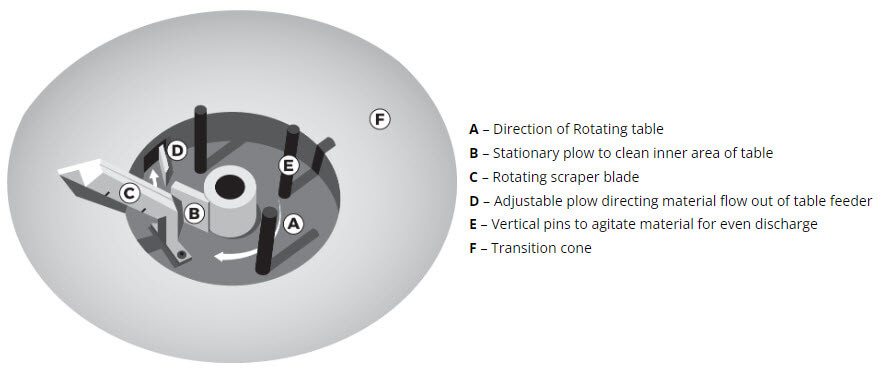

As with any process line, the proper configuration of equipment is required for maximum performance benefits, and Lancaster Products’ rotary table feeders provide a variety of features to ensure the right configuration for your needs. Table feeder benefits include:

- Variable flow rates achieved easily by adjusting the discharge plate angle, table rotation speed, and/or plow angle

- Ability to handle difficult flowing materials

- Gentle handling of green or weak materials

- Prevents material bridging

- A variety of table dimensions and storage volumes (20” diameter, 42” diameter, and 60” diameter standard sizes with custom sizes available)

- Multiple exit points (if required) to feed multiple downstream processes

Contact us today to learn how rotary table feeders can convert your batch process to continuous batch processing

717-273-2111