Many reasons compel industrial operations to enlarge solid particles for handling. Some objectives may be: enhancing flow properties, recycling, de-dusting, densifying, freezing ingredient distribution, improving mold filling properties, etc. Size–Enlargement in the powder technology context include: agglomerating, pelletizing, granulating and briquetting. This article deals with particle enlargement generally through a snowballing mechanism, with some shear action, but without the application of high pressure or extrusion.

Most powders having the ability to fuse, or slightly dissolve in the presence of a liquid, can be granulated quite easily. Others may be coaxed to form granules by the introduction of some suitable binders. The binders may act as a medium for the solid particles to adhere to each other by modifying interfacial activities. Some may form a matrix to capture the particles. Others may involve chemical reactions to achieve the objective.

Mix-granulation versus Disc / Pan Granulation:

Disc granulation (sometimes called pan granulation) is a continuous process. In its simplest form, powders and liquid are fed in steady streams and fixed proportions. The rotating disc is tilted at a certain angle to facilitate continuous overflow of the desired granules. Under steady-state conditions, particle residence time in the disc granulator is theoretically constant; hence product characteristics are also constant. Generally, disc granulation produces relatively uniform-sized granules in the order of 1/2” diameter and larger.

Instantaneous steady-state mass flow must balance for continuous granulating processes. However, as with many continuous processes, truly steady-state conditions are fleeting for disc granulation, requiring periodic operator attention, if not frequent intervention.

Mix-granulation in a Lancaster K-series high shear mixer is done in batches and is tightly repeatable. The ability to produce products of the same characteristics batch-to-batch allows the operation to be automatic, with little operator attendance. The process produces a wider spectrum of granule sizes, from micro sizes to as large as 8 -10 mm depending on requirement and feed material. Because of higher shearing and configurable tool actions, granules are generally packed more tightly, stronger and require less liquid/binder. Other properties can be controlled to a significant degree according to objectives. Mix-granulation also has the flexibility of approaching the final moisture content either from the dry end or from the wet end.

As the Lancaster mixer is capable of inputting intensity and energy, independent of mixing-granulating time, a number of factors can be adjusted to influence granule characteristics. These mixer configurable parameters include: rotor design, rotor speed, direction and granulating time and pan speed. In addition, optimizing process parameters such as solids fineness, binder, liquid-to-solids ratio and liquid addition rate can enhance desired granule properties.

Lancaster K-series mixers are especially useful for processes where some multi-ingredient solids need to be well mixed, and then granulated into nominally spherical products. Mixer and process parameters can be controlled to achieve desired properties. Size distribution usually follows a bell-shaped curve, with approximately 90 percent of granules falling within one order of magnitude.

Mix-Granulating Cycle:

Mix-Granulating Cycle:

- Charge Powders

- Dry mix (this step can be skipped with single component powder feed)

- Add liquid

- Wet mix and form seed

- Granulate

- Discharge

A door-to-door cycle can run anywhere between 3-4 minutes to over 10 minutes, depending on process and product requirements.

Peripheral Operations: Many productions can utilize the entire batch in downstream handling. Others may require a narrower cut, hence necessitating a screening and recycling step. Still others may require some type of drying, conditioning or calcining step to achieve their final properties.

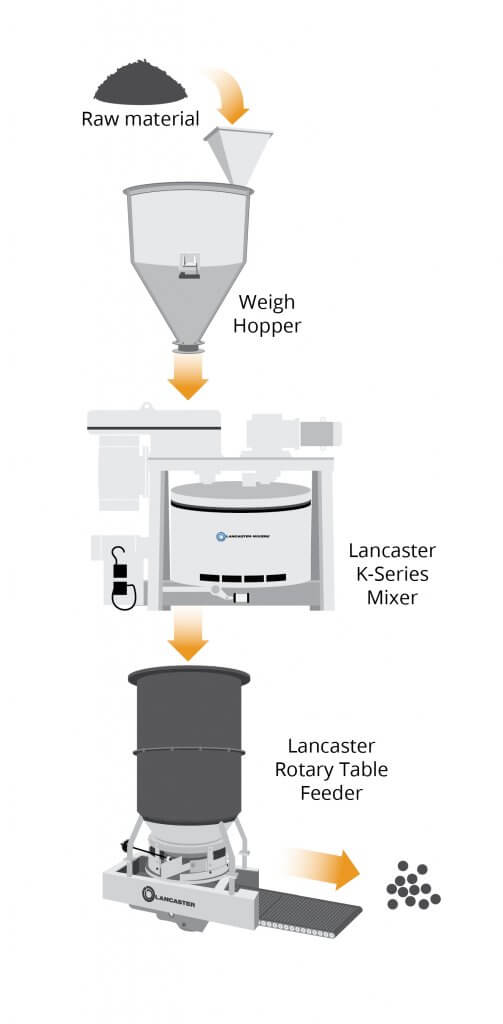

An example of a mix-granulating plant is illustrated to the right.

Call 1-800-447-7351 or Contact Us to see how CONTINUOUS BATCH MIX-GRANULATING PROCESSING can increase your mix quality and productivity.