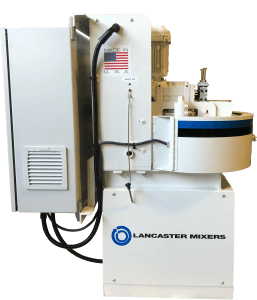

We are excited to announce several recent improvements to the design of our low shear mixer product line. These mixers are often pushed beyond the limits of other mixers due to their widespread use in mixing dusty, abrasive, corrosive, highly viscous or explosive materials. The enhancements listed below were designed to improve the performance of our low shear mixers and to minimize maintenance and repair costs, which lowers the overall lifetime cost of ownership for our clients.

We are excited to announce several recent improvements to the design of our low shear mixer product line. These mixers are often pushed beyond the limits of other mixers due to their widespread use in mixing dusty, abrasive, corrosive, highly viscous or explosive materials. The enhancements listed below were designed to improve the performance of our low shear mixers and to minimize maintenance and repair costs, which lowers the overall lifetime cost of ownership for our clients.

- Split drivetrain: pan and tooling on separate drives

The counter-rotating pan and tooling are now operating on separate drives allowing for individual control of tool and pan speeds. This simple split drive design provides increased flexibility to customize mixing recipes for different materials as compared to a single vertical shaft. Maintenance and trouble- shooting of issues relating to the pan or tooling also become easier.

- Updated gearmotors

Off-the-shelf SEW drives provide improved efficiency and the ability to start machine operation under load at higher torques. This enhancement reduces drive wear, extends drive life, reduces maintenance time and costs.

- Nylon pinion

N ylon pinion use offers many operating and maintenance benefits over steel pinions. The lighter weight nylon pinion is self-lubricating which eliminates the need for maintenance of this part. As an engineered failure point, the pinion will break and halt machine operation if an issue occurs that prevents the pan from rotating. This prevents further damage to pan gear and reduces repair costs. In addition, a removable bearing access in the updated design allows for easier access for ease of changing pinion and maintenance.

ylon pinion use offers many operating and maintenance benefits over steel pinions. The lighter weight nylon pinion is self-lubricating which eliminates the need for maintenance of this part. As an engineered failure point, the pinion will break and halt machine operation if an issue occurs that prevents the pan from rotating. This prevents further damage to pan gear and reduces repair costs. In addition, a removable bearing access in the updated design allows for easier access for ease of changing pinion and maintenance.

- Upgraded coupling

Elastomeric coupling has been implemented with side removable inserts. This provide the user easier access for maintenance practices.

- Safety Features

Pan guarding and a pan guard safety switch have been incorporated to improve machine safety and prevent the mixer from operating before safety mechanisms are engaged. The addition of a head-in-position safety switch prevents the machine from operating before the mixing tools are locked in place.

Pan guarding and a pan guard safety switch have been incorporated to improve machine safety and prevent the mixer from operating before safety mechanisms are engaged. The addition of a head-in-position safety switch prevents the machine from operating before the mixing tools are locked in place.

- Electrical Features

The custom control panel has been upgraded with integrated VFDs which allows for greater flexibility for individual control of pan and tool speeds for better mixing outcomes. Optional user controls for speeds are now available. Safe Torque Off safety components have also been incorporated. This set up also allows for a wider array of input voltage conditions.

- Linear Guide Bearings for Sliding Head Assembly

New linear guide bearing eliminate metal-to-metal sliding contact and reduce the force required to move the head. Manual or pneumatic solutions are now offered based on customer preference.

- Frame Re-Design

Improved frame design incorporates more access panels for ease of maintenance.

Contact us today with your Low Shear Mixer requirements and we’ll match you with the right mixer for your needs.

717-273-2111