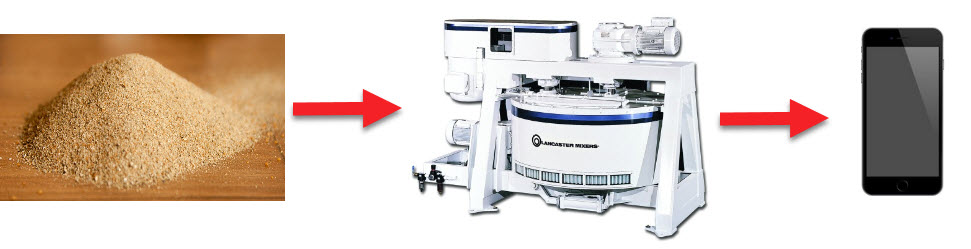

If you’ve ever watched a flat-screen television or used a smart phone there’s a good chance the glass showing the picture was made by machinery developed and produced by a Lancaster Products high shear mixer in Lebanon, Pennsylvania.

Image for illustration purposes only

Lancaster Products designs and manufactures mixers and glass crushers used in glass processing and recycling to meet the ultra-critical specifications demanded by electronics manufacturers. The materials used to manufacture LCD and OLED glass must meet very critical specifications including homogeneity of particle size and chemistry in order to demonstrate the properties required for proper functionality as an end product. The glass used in television sets and cell phones is extremely thin, less than the thickness of a sheet of paper. Two pieces are used to form LCD (liquid crystal display) and LED (light-emitting diode) screens which are used in cell phones, flat-screen monitors and televisions.

Lancaster Products’ connection to television glass began in 1992, when we were approached to develop a mixer for a new process to make high-precision flat-panel glass for LCD televisions. Fast forward a few decades and the ‘cell phone revolution’ emerged increasing the demand for flat panel glass in the ever-evolving electronics industry. As the demand for flat panel glass took off in the consumer market, Lancaster Products has been at the forefront, producing equipment for the industry. Curt Snyder, President of Lancaster Products, notes that a vast majority of the world’s thin glass is processed by Lancaster equipment. “Our mixers and crushers have become a staple for the production of flat panel glass. It has been a fantastic market and we are gracious to be a vital part of such an important global market”, says Snyder.

Contact us to learn more about our glass processing options

717-273-2111