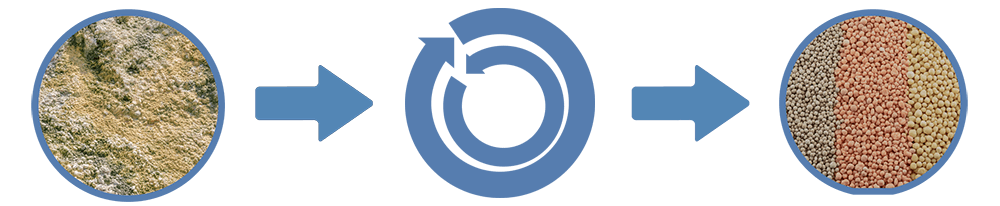

Lancaster Products Mixing technology transforms waste streams into valuable products.

Lancaster Products High Shear Mixers are used in a wide variety of industries to repurpose waste materials into viable products. Waste materials can be mixed, densified and agglomerated in the same operation – allowing waste materials to be reintroduced into production streams or to be used as a stand-alone or additive in separate products.

Repurposing WASTE material application

Lancaster Products High-Shear Mixers have been used successfully to re-purpose previously discarded materials for use in the development of new products or reintroduction to production streams. This results in a more environmentally friendly handling of material as well as reducing hazardous waste that is landfilled, stored in ponds etc.

Some applications include:

- Pelletizing waste by-product sulfur for fertilizer

- Pelletizing carbon black for flowability and better handling

- Pelletizing synthetic gypsum for fertilizer

- Agglomerating of fly ash for building and road aggregate

- Granulating fly ash into cold set ceramic

- Repurposing dry scrubber material into lightweight cat litter

- Pelletizing iron oxide dust for re-introduction into production furnaces

- Pelletizing raw chicken manure for use in fertilizers.

ONE MACHINE ONE PROCESS

The high intensive action of the Lancaster High Intensive Mixers provides the opportunity to use relatively small amounts of additive materials needed to transform a waste material. The smaller amounts of additives mean lower production costs when using a more expensive material that may provide added product benefits.

Call 1-800-447-7351 or Contact Us to talk to a Lancaster Products Representative about your waste repurposing needs.