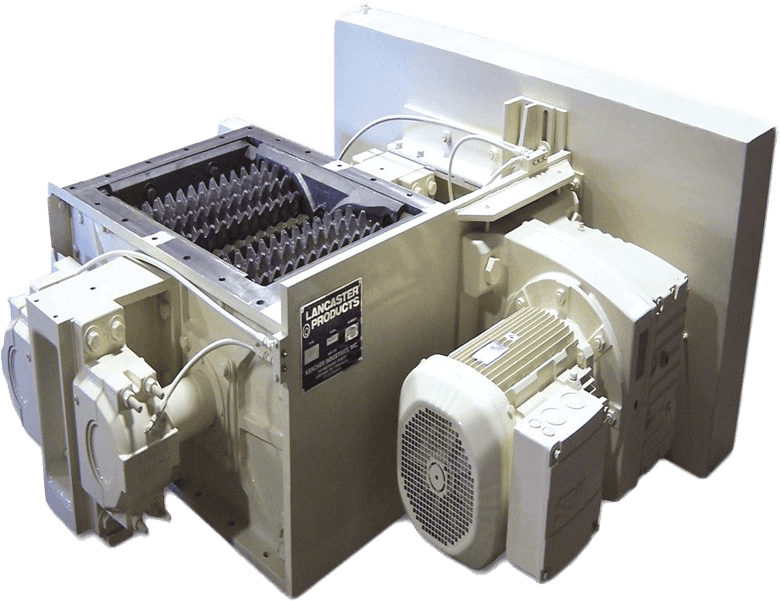

Lancaster Products Roll Crushers reduce difficult-to-crush material in a single pass.

Lancaster Products Roll Crushers are designed for long life with a minimum of maintenance. These crushers reduce – in a single pass- material previously requiring primary and secondary crushing. The crushing rolls turn toward each other, confining all crushing to the area where the teeth mesh. Both rolls are timed to rotate at the same speed to maintain a true – and highly effective – crushing action.

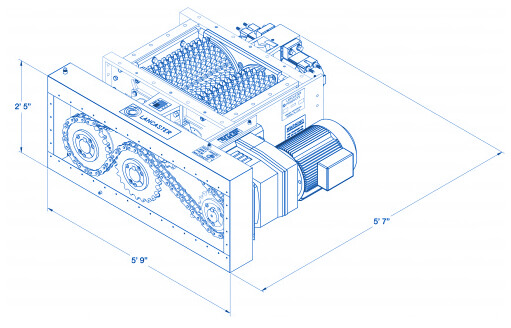

Guards are not shown in crusher area for clarity

CONSTRUCTION

The Lancaster Products Roll Crusher is a compact unit built around a rigid cast frame. It is powered by a VFD gear drive unit. The high alloy steel shafts are driven by a heavy-duty chain operating in an enclosed oil bath. All parts coming in contact with the process material are replaceable and are made of wear-resistant alloys. Replaceable comb plates and cheek plates at the ends and sides of the housing prevent material from bypassing the rolls.

- Crushing teeth are cast of a hard and tough alloy in replaceable segments.

- The large oversized bearings are outboard, self-aligning and protected by mechanical seals.

- Protection from shock loads is provided through the VFD.

- Shaft outlets in the frame are equipped with mechanical seal assemblies.

- Oversized, sealed, spherical roller bearings are supported by large castings rigidly mounted to the crusher frame castings and remotely located from the crushing area.

HOW IT WORKS

Lancaster Products Roll Crusher rolls rotate toward each other, confining all crushing to the area where the teeth mesh.

- Both rolls are timed to rotate at the same speed to maintain a true crushing action.

- All material entering the crusher pass through the mounted twin shaft rolls.

- Since the relative positions of shafts are rigidly fixed, any trapped material will not separate the rolls. This prevents oversize material from passing through the crusher.

- Crushed particle size can be varied from ¾ inch to 2 inches by changing the distance between the twin crushing rolls. Top and bottom openings have drilled mounting flanges. The crushing gap is adjustable by shimming the pillow blocks.

LANCASTER ROLL CRUSHER MODELS

Lancaster Model 12 x 18 Roll Crusher |

Lancaster Model 48 x 32 Double Roll Crusher |

|---|---|

Roll opening: 12″ x 18″ |

Roll opening: 48″ x 32″Each roll opening: 24″ x 32“ |

Drive: 5 HP |

Drive: 30 HP |

Capacity: Up to 3 ton/hour |

Capacity: Up to 60 tons/hour |