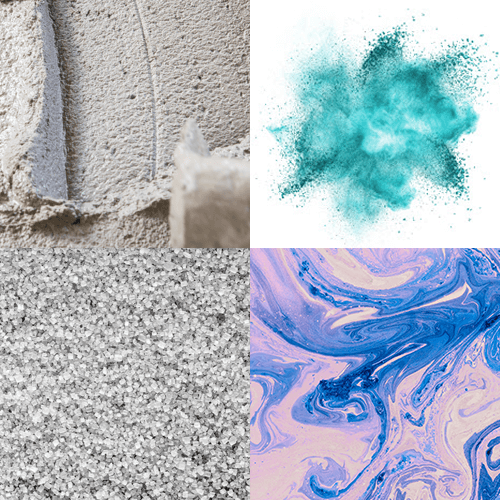

Other Materials

The versatility of Lancaster Products Mixers and Material Handling Equipment is deep and wide. From molding sand to powders to fertilizer… we offer an integrated solution for mixing, pelletizing and granulating with our high-performance equipment, services, and support.

Molding Sand | Foundry

Lancaster Products manufactures high shear mixers for the efficient preparation of bentonite bonded molding sand. Lancaster Products low-shear, muller style mixers are used for molding sand preparation in the foundry industry. A complete molding sand system design and supply by Lancaster Products can provide a single source solution for the end foundry user.

The advantages of the Lancaster Products system:

- Excellent flowability of mixed sand

- Uniform strength values due to the consistent mixing process

- Compaction requirements for the sand can be met on a consistent basis

- Distribution of water in an efficient manner when added to the mixture

- Consistent mixing of the return sand, additives and new sand in the Lancaster High Shear Mixer

Metallurgy | Powder

Lancaster Products High Shear Mixers are used extensively in the blending, mixing and granulation of powder metallurgy raw materials. Our mixers can be used to granulate the raw metal powders to ensure a homogeneous mixture.

The powders can also be granulated in the mixer to provide uniform mixtures and a more uniform flow into the press mold. This translation can be done under atmospheric conditions or even an inert gas blanket when required. The upper pan seal on the Lancaster Mixer allows the mixing pan to be purged with inert gas. Inert gas leakage is minimized by concentrically machined rings that make up the grease filled labyrinths seal arrangement.

This granulation process can improve the overall quality of thru parts pressed and also increase the density of the powder before pressing. This increased density prior to pressing results in a higher density and stronger part after pressing.

RECOVERING WASTE STREAMS / BENEFICIAL RE-USE

The Lancaster Products High Shear Mixer can be used to recover the waste streams and dust for a variety of industries. For example, in a steel mill, waste streams can include floor sweeping, dust collected from the cupola and other general baghouse dust collected throughout the process. These materials can then be combined and blended with a binding agent to allow reintroduction into the production stream.

The Lancaster Products High Shear Mixer can be used to blend and begin the granulation process for the production of iron ore pellets. The Lancaster Mixer can mix and pelletize in a single process where iron ore is mixed with bentonite or Portland cement to ensure a homogeneous mixture. This reduces the amount of bentonite required to create iron ore pellets when compared to other blending or pelletizing solutions – significantly reducing the cost of producing green iron ore pellets.

Raw | Friction Materials

The Lancaster High Shear Mixer provides a higher quality mix of friction materials for typical clutch and brake pad application. The higher intensity mixing action results in a more homogeneous mixture and a reduction in the total processing time required. Lancaster Products can provide a single source solution for the friction materials end user.

The Lancaster High Shear Mixer can be used to produce the required friction lining batches with the following properties:

- A mixture that is more homogeneous than a low intensity mixer.

- The level of intensity can be adjusted to meet the needs for the final mixture.

- Capable of mixing the raw materials even when they include the addition of a fiber component.

Refractory Materials

Lancaster High Shear Mixers are used worldwide in the preparation of raw materials with reduced processing times for all forms of refractory materials. Refractories are important to high-temperature manufacturing. They are critical to industries such as glass, ceramic, and metallurgy by thermally insulating equipment, thereby protecting personnel and equipment, and saving fuel.

Typical types of refractory components:

- Molding compounds for standard and lightweight refractory bricks

- Compounds used for casting final shapes

- Compounds used for pressing final shapes

- Ceramic materials that contain fibers for increased strength

- Dry mixing of materials for field installation

- Compounds used for plastic refractories

- Ceramic materials that contain fibers for increased strength

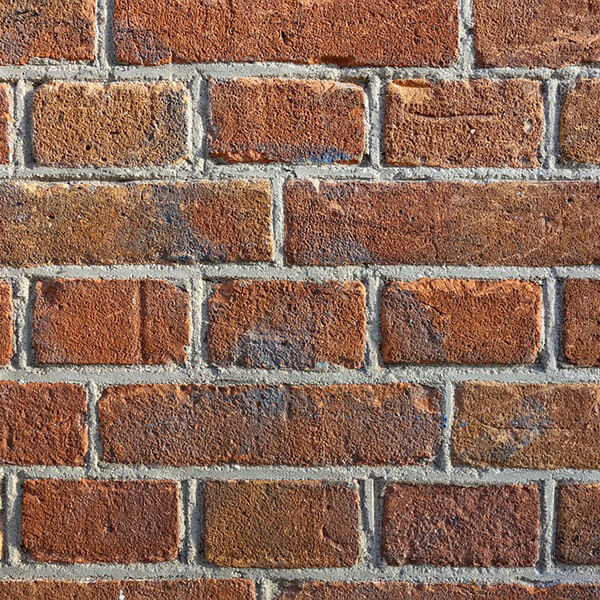

Molded Bricks

Lancaster AutoBrik Machines produce a high-quality sand-molded brick and water struck brick for the building industry. The PLC controlled, hydraulically actuated Model 46H AutoBrik Machine is capable of producing up to 18,000 molded bricks per hour.

This design has proven to reduce maintenance costs and improve total operating efficiencies- while maintaining the molded brick style that brick markets have come to appreciate and that brick producers have found so profitable. This has made the Lancaster AutoBrik one of the most reliable and effective brick presses on the market.

Call 1-800-447-7351 or Contact Us to talk to a Lancaster Products Representative about your material processing needs.