Fertilizer

With the ability to mix and granulate in a single step and process, Lancaster Products K-Series Mixers provide fertilizer manufacturers the most efficient way to create high value, complex fertilizer products.

Market demands on fertilizer specifications leave manufacturers with a difficult task of creating the perfect solution for their customers. With traditionally complex, multi-step and multi-equipment designed processes, the high costs of time, energy and maintenance can be an obstacle for market entry or reduced profitability. Lancaster Products K-Series Mixers create significant opportunities for fertilizer manufacturers who already have an established process as well as companies looking to develop new products or turn materials previously viewed as waste into valuable fertilizer products.

BENEFITS OF GRANULATING FERTILIZER

Fertilizer provides important nutrients, minerals and other novel ingredients to improve the performance of soil and crops. The delivery and absorption of these nutrients is vital to the successful growth of plant life. Common concerns with powdered fertilizer delivery include excessive dust upon application, washing away of fertilizer prills with rain and watering, and uneven delivery of desired ingredients.

Granulating fertilizer products can provide the following solutions:

- Fertilizer stays put and are available for absorption over a longer time period than powdered or liquid fertilizer.

- Reduced fertilizer run off into the watershed

- No dust during application – more fertilizer reaches targeted areas and not lost in transportation or application due to dusting

- Homogeneous complex granules ensure all ingredients are in each granule in equal proportions for even distribution of nutrients. This provides superior nutrition compared to blended fertilizer products where particles tend to segregate by density and spread nutritionally unequally over the target area when compared to a complex pellet application.

10 Reasons to Manufacture Fertilizer in a Lancaster Mixer

- Granules stay put – not washed away by watering or rain

- No dust during application

- Homogeneous granules ensure all nutrients/ingredients in each granule

- Reduced machinery footprint

- Operates with High moisture raw materials

- Custom control of product sizes

- High on-size yields

- Reduced production times

- Reduced system complexity

- Reduced binder use

SIMPLIFY YOUR PROCESS & INCREASE ROI

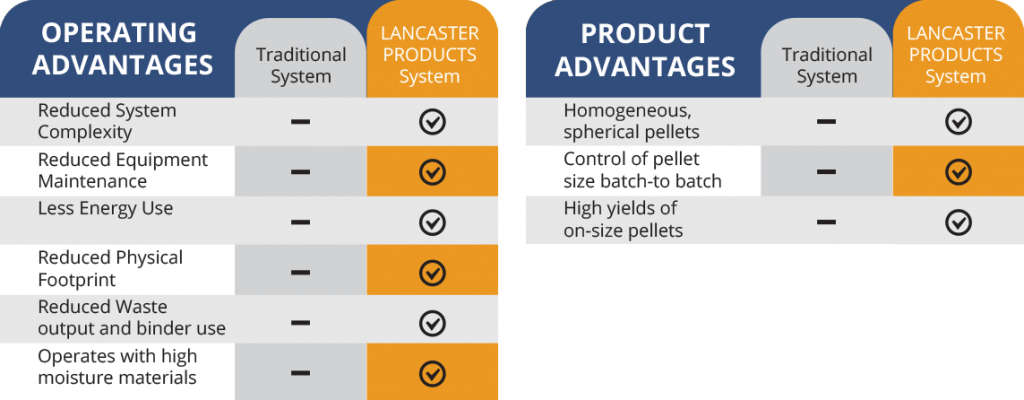

Current fertilizer manufacturing processes typically involve multiple steps with many different pieces of machinery for drying, milling, mixing and agglomeration. Limitations with use of high moisture raw materials require initial drying prior to processing which adds additional time and energy costs to the manufacturing process. Using pin mixers or other similar mixers with disc pelletizers or pellet mills require the addition of large and imprecise amounts of binders and water to create a final product. Lower yields of specific size ranges of pellets with these types of pelletizing processes lead to reprocessing of materials.

Current fertilizer manufacturing processes typically involve multiple steps with many different pieces of machinery for drying, milling, mixing and agglomeration. Limitations with use of high moisture raw materials require initial drying prior to processing which adds additional time and energy costs to the manufacturing process. Using pin mixers or other similar mixers with disc pelletizers or pellet mills require the addition of large and imprecise amounts of binders and water to create a final product. Lower yields of specific size ranges of pellets with these types of pelletizing processes lead to reprocessing of materials.

The Lancaster Products K-Series Mixer utilizes a high shear, counter-current mixing action to mix and granulate in one-step, eliminating the need for multiple pieces of equipment. With the ability to begin with higher moisture raw materials (up to 50% depending on material properties) than traditional systems can handle, the initial drying and consequent milling steps are eliminated or greatly reduced. As a consequence, energy consumption of the system is also reduced, thereby lowering operating costs.

Reduced levels of binders and water are required because of the highly effective dispersion of additives throughout the main ingredients. By optimizing the additive levels, waste, typically found in less precise systems, is eliminated.

The counter-current mixing action in a Lancaster Mixer utilizes a high-speed rotor, plow and counter-rotating pan to continuously move materials into the path of the mixing tool so granulated material is homogenously coated throughout the mix, eliminating the need for overages of additives to assure agglomeration.

The independently controlled mixing tools provide flexibility to achieve high yield product specific fertilizer size ranges. The programmable controls allow for highly repeatable batch results as well as producing differing size pellets batch-to-batch with the touch of a button.

At the end of the day, the Lancaster Mixer produces a superior product at a higher throughput with higher on size yields for a lower operating cost resulting in an increase ROI for our customers.

MATERIALS & USES

Lancaster Mixers are being used in the manufacturing of fertilizer with organic and inorganic raw materials. Our customers produce high value homogenous granules with complex dissimilar ingredients that are broadcast spreadable, with minimal equipment and energy requirements.

Organic

Our customers produce high value homogenous granules with complex dissimilar ingredients that are broadcast spreadable, with minimal equipment and energy requirements.

Materials used: Manure, chicken litter, Biochar, animal meal, humic acid, compost, biosolids

Inorganic

Lancaster Mixers produce high yields of on size product of AG-lime, Rock Phosphate, Gypsum, and other inorganic fertilizers and soil amendments.

Materials used: lime, synthetic gypsum, Ammoniums, Calcium, Phosphates, Potassium, humates

Applications for Complex Pelletized Fertilizer

- Golf course maintenance

- Residential application

- Commercial farming

- Organic farming

- Landscaping

- Sports field maintenance

Resources

Call 1-800-447-7351 or Contact Us to talk to a Lancaster Products Representative about your fertilizer processing needs.