Most technical books on mixing equipment rarely include information about Counter-Current High Shear Mixers. Yet, these mixers have been successfully satisfying industrial mixing needs for over half a century. So, how are they different from, and in many ways superior to, other mixer designs?

To best understand the benefits of a counter-current high shear mixer we’ll use the common home kitchen mixer for comparison, as both types of mixers share key components such as an agitator and a vessel where the mixing occurs. In kitchen mixers the agitator is mounted to a motor and the vessel remains locked in place and the rotational axis of the agitator may be fixed or move in an orbit. After mixing our ingredients for some time, we stop the agitator and scrape the bowl to get the unmixed materials near or adhering to the walls to where the agitator runs for better dispersion. We re-start the agitator to finish the mixing step before transferring the wet cake mix to a baking tray, again scraping with a spatula to make sure all the mix is transferred.

The example above highlights some critical areas that beg improvement when applying this general mixer design on a full scale production level for industrial processes. Without improvements, unmixed or under-mixed materials will remain, which results in lower yields and a less homogeneous mixture. And those manual-assist steps, which we don’t think twice about when preparing a cake mix, become big issues given the proliferance of high speed plant automation in today’s industrial facilities.

To improve mixing, the number of agitators or area of sweep can be increased but this increases the risk of accidental collision from vibration and forces a reduction in speed, hence offsetting the goal to both mix effectively and clean the wall of buildup. Added tools also crowd out the mixer interior. The inevitable observation is that a stationary vessel cannot satisfactorily minimize wall build up and maximize mixing effect.

The recognition of the problems outlined above led to the design of counter-current high shear mixers as the solution.

General Design Concept: Counter-Current High Shear Mixer

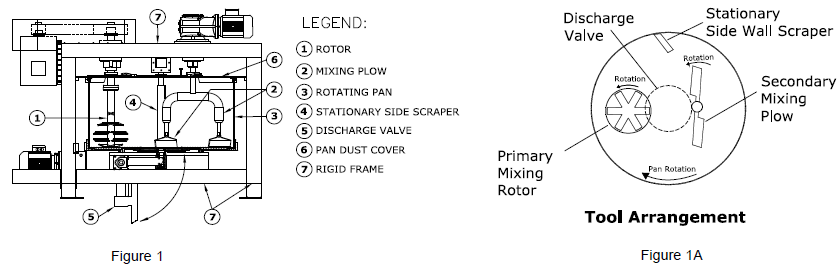

Consider the kitchen mixer again. What if we mount a stationary spatula against the bowl and now make the bowl turn? Indeed, a rotating pan mixer does exactly that! The rotating pan (i.e. the bowl or vessel) runs at a slow enough rpm to be safe from vibrational collision but sufficient to accelerate the mix materials to the agitator by placing the spatula at an ideal location and deflection angle. The Side Scraper + Rotating Pan practically eliminate any dead zones in the mixer which allows for a more completely homogenized mix without having to stop the process for operator intervention.

The rotating pan provides macro material transport. Mixing is performed by the agitators (i.e. Rotor & Mixing Plow) which are mounted in fixed positions. The rotors can be relatively small, as the mix materials are channeled to it by the rotating pan and the side scraper. This design has the added advantage of leaving ample space within the pan for maintenance purposes.

The “counter-current” reference of this type of mixer originally comes from the Plow which is a secondary agitator in the mixer. The plow rotates at a moderate speed, allowing it to be set close to the pan floor to prevent material buildup there. The plow also rotates on a fixed vertical axis and counter-current to the rotating pan, thus creating 3-dimensional mixing actions and aiding in material discharge when mixing is complete.

The plow and the side scraper working in conjunction with the pan can discharge a full batch in seconds. In most cases, 90% of the batch will have left the mixer within 5 seconds. It is typical to see no more than 10 pounds of materials left at the end of discharge. On a 3,000-pound batch, this is equivalent to less than 0.3%. Other types of mixers can leave as much as 5% or 150 pounds between batches, which requires significantly more labor to the process.

Call 1-800-447-7351 or email us to talk to a Lancaster Products Representative to find out more about the advantages of a counter current high shear mixer.