Blog-News

Lancaster Products Multi Tool Mixing Advantage

Since the introduction of the original K-series mixer in 1986, Lancaster Products High Shear Mixers have been designed to produce the best mixing and pelletizing results for our customers. Lancaster Mixers superior performance is due to our multi-tool configuration, counter current mixing action and variable tooling speed capability.

Multi Tool Configuration

Lancaster Mixers can be configured with three independent variable speed mixing tools: the mixing rotor, the plow and the rotating pan. These three tools work in concert to provide the best mixing results. The primary mixing tool is the high-speed rotor. The plow and rotating pan both work to move material into the main rotor’s path. The three mixing tools are so efficient at mixing, there are no dead spots inside of the mixing cavity and every piece of material passes through the mixing rotor every few seconds. Additionally, a sidewall scraper is positioned against the pan sides to prevent caking and buildup of material on the pan itself.

Benefits of Owning Lancaster Products’ High Shear Mixers

We are very thankful for all the positive feedback we’ve received over the past 30 years of enhancing materials processing projects for our clients with our high shear mixers. So, we decided to highlight some of the reasons our customers choose to partner with Lancaster Products to optimize their industrial mixing and pelletizing processes.

We are very thankful for all the positive feedback we’ve received over the past 30 years of enhancing materials processing projects for our clients with our high shear mixers. So, we decided to highlight some of the reasons our customers choose to partner with Lancaster Products to optimize their industrial mixing and pelletizing processes.

-

-

- Practical Machine Design

- Easy Maintenance

- Easy Clean Out

- Customization

- Low Total Cost of Ownership

-

Operational Life Expectancy of Lancaster High-Intensive K-Series Mixers

Lancaster Products High Shear Counter-Current Mixers are highly effective in their ability to mix and pelletize in one machine and one process, but Lancaster Mixers are also built to last. Many of our machines are still operating after decades of use. We continue to supply parts to many vintage year machines still in operation.

Lancaster Products machines are built with a robust construction that provides structural durability and are designed to allow for replacement of wear parts as needed to extend the operational life of our machines instead of total machine replacement. To our customers this translates to lower Total Cost of Ownership and higher return on investment than other mixers. With proper maintenance, Lancaster Products mixers are very long-lived machines.

Lancaster Products machines are built with a robust construction that provides structural durability and are designed to allow for replacement of wear parts as needed to extend the operational life of our machines instead of total machine replacement. To our customers this translates to lower Total Cost of Ownership and higher return on investment than other mixers. With proper maintenance, Lancaster Products mixers are very long-lived machines.

Infographic: Lancaster Products Materials Testing Process

Lancaster Products is dedicated to process and mix design optimization. Whether you are looking to develop a new process/product or improve on an existing process, Lancaster Products can help. From mixing to granulating or pelletizing, our experienced application engineers can design toward many objectives, including: mixing cycle times, binder and minors optimization, homogeneity, particle hardness, moisture and air entrainment, particle size distributions and yields.

Lancaster Products is dedicated to process and mix design optimization. Whether you are looking to develop a new process/product or improve on an existing process, Lancaster Products can help. From mixing to granulating or pelletizing, our experienced application engineers can design toward many objectives, including: mixing cycle times, binder and minors optimization, homogeneity, particle hardness, moisture and air entrainment, particle size distributions and yields.

Lancaster Products Announces New Website Launch

January 4, 2019

For Immediate Release

LEBANON, Pennsylvania – The new and completely redesigned website offers visitors richer insight into the Company’s high efficiency mixing, pelletizing and crushing solutions for a wide variety of industries and materials.

LEBANON, Pennsylvania – The new and completely redesigned website offers visitors richer insight into the Company’s high efficiency mixing, pelletizing and crushing solutions for a wide variety of industries and materials.

What to Expect from Lancaster Products High Shear Mixer Sample Testing

Our last post focused on our experience in concept testing and how it applies to our high shear mixer sample testing process. This post will dig in a little deeper and provide insight into the breadth of data we provide to our customers when they commission Lancaster Products to provide sample testing for them.

Our last post focused on our experience in concept testing and how it applies to our high shear mixer sample testing process. This post will dig in a little deeper and provide insight into the breadth of data we provide to our customers when they commission Lancaster Products to provide sample testing for them.

Over the past 30 years, we have collaborated with our customers to perform proof of concept testing in our K1 laboratory mixers for thousands of materials samples. The desired outcome of the testing is customer dependent but typical requirements are along the lines of pelletizing/granulating to specific size ranges and desired yields, mixing to achieve homogenization, or reduced reaction times of existing processes. Outcomes provided are 1) proof of concept in achieving the desired product, and/or 2) optimization of the current mix processes. Our engineers perform the tests in our controlled laboratory, log all key information in our database, and share all data with our customers for future reference. Below is a list that summarizes some of the information we collect during every test run we perform:

Introducing Lancaster Products High Shear Counter-Current Mixer Recipe Development

Introducing Lancaster Products High Shear Counter-Current Mixer Recipe Development, the first in a category of posts designed to provide insight into our deep experience in developing thousands of pelletized and granulated formulations over the past 30 years.

Introducing Lancaster Products High Shear Counter-Current Mixer Recipe Development, the first in a category of posts designed to provide insight into our deep experience in developing thousands of pelletized and granulated formulations over the past 30 years.

We develop custom recipes or mix designs for our customers that are rooted in our deep mixing and pelletizing experience. Because every customer’s materials, parameters and processes are different, each requires a unique mix design. In performing proof of concept testing, we have worked with our customers on a wide variety of materials and binder combinations across many different industries. While specific formulations belong to our customers, we have learned a tremendous amount from our experiences with various materials and we wanted to highlight the science that goes into every formulation developed by our materials processing engineers.

High Shear Counter-Current: Simply the Most Effective Mixing Technology Available

High shear counter-current mixers from Lancaster Products simply employ the most effective mixing technology available.

- Features

- Game Changing Mixing Technology

- Applications

- Materials Processing

- Performance Features

- The Most Effective Mixing Technology

Download the Lancaster Products High Shear Counter-Current Mixing Technology Brochure

The Role of Binders in High Shear Mixing, Pelletizing, and Granulating

Binders are a key ingredient in agglomerating, granulating and pelletizing applications. Considered an inactive ingredient, Binders are critical in allowing for agglomeration and holding the structure of the pellets together. Many of our customers are pleasantly surprised of how efficiently the Lancaster High Shear Counter Current Mixer can pelletize utilizing low amounts of binders when compared to alternate methods of granulation. The advantage lies in the Lancaster Mixer’s ability to rapidly homogenize tiny amounts of minor ingredients into large amounts of majors. Because the binder is so efficiently dispersed throughout the mix, only the optimal amount of binder is used. Less effective mixing techniques require more binder than in a Lancaster Mixer, because the binder is not as effectively dispersed throughout the mix.

Binders are a key ingredient in agglomerating, granulating and pelletizing applications. Considered an inactive ingredient, Binders are critical in allowing for agglomeration and holding the structure of the pellets together. Many of our customers are pleasantly surprised of how efficiently the Lancaster High Shear Counter Current Mixer can pelletize utilizing low amounts of binders when compared to alternate methods of granulation. The advantage lies in the Lancaster Mixer’s ability to rapidly homogenize tiny amounts of minor ingredients into large amounts of majors. Because the binder is so efficiently dispersed throughout the mix, only the optimal amount of binder is used. Less effective mixing techniques require more binder than in a Lancaster Mixer, because the binder is not as effectively dispersed throughout the mix.

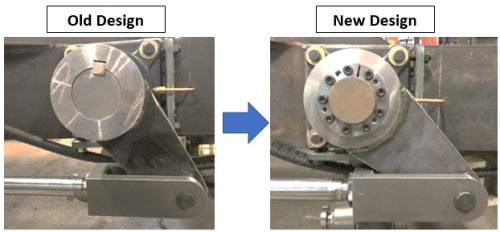

Lancaster Products High Shear Mixer Design Enhancements – Discharge Assemblies

Lancaster Products has introduced design enhancements to the K-Series High Shear Counter Current Mixer line. Through our continuous improvement initiatives our engineers identified various areas of design refinement focused on improving our customer’s maintenance experience, reducing manufacturing time and enhancing the mixer’s overall design. We are featuring our new and enhanced discharge assembly design.

Keyless connections

Keyless connections

Lancaster Product engineers created a simple yet elegant solution to improve the discharge valve design by moving from a keyed assembly to a keyless locking device. The new design is less complex than its predecessor and performs better than the previous discharge style. The new keyless connection enhances performance over the old design and will be easier to maintain and service.